Cire Technologies, Inc. has successfully designed, fabricated and started-up a new custom flotation dryer for a new paper laminating line. The dryer was delivered completely assembled, requiring very little installation cost. It was delivered on time and on budget.

The dryer supports the web on air for twelve feet. Characteristics of the dryer include:

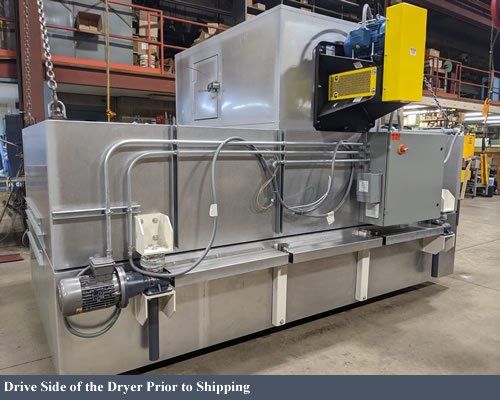

- Flotation nozzles above and below the web. The gap between upper and lower nozzles is adjustable and was set at 3/8 inches. The nozzles and supply plenum are fabricated out of stainless steel, the balance of the dryer is aluminized steel, per the customer’s request.

- The dryer can operate up to 400° Heat is provided by a Maxon Corporation, Ovenpak, natural gas nozzle burner. The complete burner system including the gas train and controls was shop mounted onto the dryer. This vastly simplified the field installation for the customer, requiring only the delivery of power and natural gas to the dryer and the installation of exhaust ductwork from the dryer to the exhaust fan and through the roof.

- Five inches of insulated wall panels provide a cool dryer exterior. Use of perforated metal between wall skins eliminate the potential of exterior skin hot spots.

- The dryer system works together with the converting machinery controls, using Allen Bradley I/O modules to communicate with the line PLC. Complete control over the dryer is achieved through the operator touchscreens, supplied by the converting machinery supplier. We worked closely with the machinery supplier to complete a turn-key installation.

- Allen Bradley variable speed drives on the supply and exhaust fans allow for operator flexibility to match the dryer performance to the product being run. These are controlled through the operator HMI touchscreen discussed above.

- An IR temperature sensor looking at the web in the last foot of the dryer provides real-time indication of the temperature of the web leaving the dryer. The exit temperature is a good tool to fine-tune the dryer operating parameters for each product.

- Screw jacks on the operator and drive side of the dryer enable the top half of the dryer to be raised up to eighteen inches above the lower half. This makes threading and cleaning maintenance easy. Interior flexible ducts between upper and lower halves of the dryer are used to convey the supply and recirculated air between sections.

For more information on how Cire Technologies, Inc. can build a custom dryer for you please Click Here.