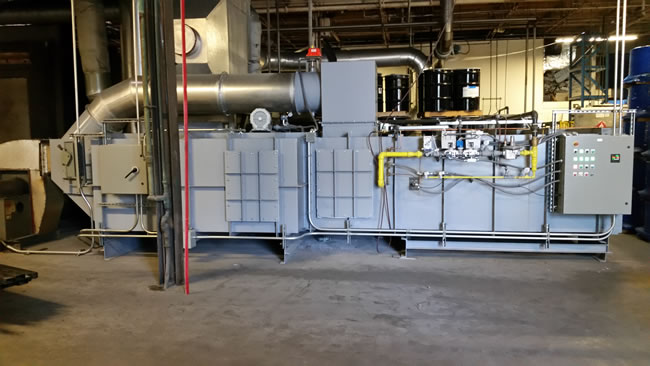

Cire Technologies has recently successfully completed the design, fabrication and installation of a new thermal recuperative oxidizer for a metal coating customer in Connecticut. The unit replaced a failing unit but reused the existing fan and stack to save some money for our customer. The oxidizer, rated for 4,000 scfm, includes a 60% efficient primary heat exchanger to preheat the process exhaust to the oxidizer, a 4,000,000 Btu/hr raw gas burner, and a combustion chamber that provides a one second dwell at 1400°F.

Stack tests of the oxidizer achieved a destruction rate of 99.96%.

The oxidizer includes a heat exchanger bypass to protect the unit against over-heating from high solvent loads, a variable speed drive for the oxidizer fan and automated ramp up and shutdown controls.