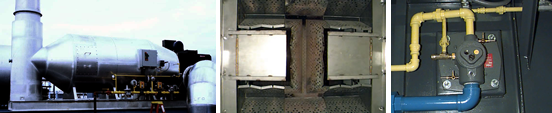

Cire Technologies has manufactured thermal afterburners since its inception. Our thermal afterburner units are used to destroy VOCs in high concentrations, to eliminate visible smoke or to destroy VOCs from processes that are operated intermittently to the point that heat exchangers are not economically feasible.

Standard to our thermal afterburners are the following features:

- Raw gas burners mounted in the air stream for complete flame contact with the process stream or nozzle burners where oxygen content or high exhaust temperatures eliminate opportunity for raw gas burner use

- Ceramic block interior insulation mounted to a plate steel exterior skin for thermal oxidizer applications

- Fully welded stainless steel interior skins in smoke eliminator applications

- Fully welded exterior skin with no possibility of leakage in high temperature applications

- Elimination of hot spots on the exterior skin by the use of superior construction techniques

- Fully piped and wired gas trains

- Complete control panels and electrical components, no hidden costs

- Destruction efficiencies of 99% or greater available

- Up to a five year warranty is available

Optional upgrades include:

- Waste heat recovery to supply process heat

- PLC and HMI control system for interconnection to plant DCS

- Process to oxidizer ductwork

Use the Quick Contact link or fill out our online questionnaire to find out more or request a quote.