Cire Technologies, Inc. proudly provided a Connecticut customer with an integrated batch oven and thermal oxidizer system. We purchased the batch oven and integrated our thermal oxidizer to provide a complete system to our customer.

The thermal oxidizer is used by the customer in a burn-off mode to eliminate odor and smoke. For the balance of the customer’s process, the oxidizer fan exhausts the oven without the burner operating.

Our oxidizer was designed to be supported above the oven. It was fully assembled on the support frame including all gas train and control components, to make the oxidizer fully operational. Installation was therefore extremely simple, with the oxidizer assembly set on the oven, supported by independent legs.

The inlet duct for the oxidizer sits on top of the oven exhaust duct, and is designed to handle oven temperatures up to 1200°F. The thermal oxidizer is an afterburner, with no heat recovery, with exhaust temperatures up to 1400°F. To handle the high oven and oxidizer temperatures, dilution air is introduced to the exhaust stream prior to the exhaust fan. The fan therefore will not see temperatures above 300°F, reducing the cost and maintenance of the fan.

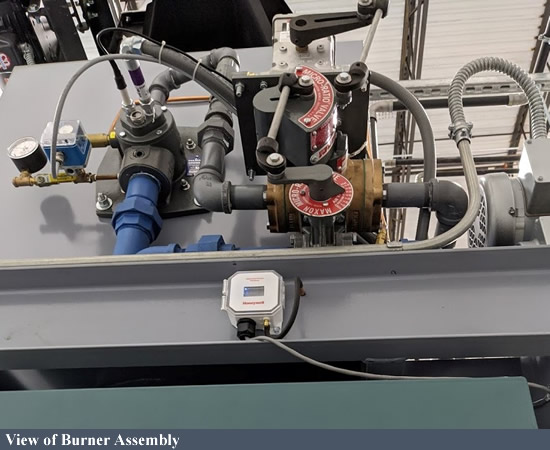

This oxidizer system includes a Maxon Corporation, Kinemax, natural gas nozzle burner. The burner setup includes a combustion air fan and a Maxon Corporation Micro-Ratio valve to control the natural gas and combustion air flows.

Simplifying the installation, complete gas and combustion air trains and the oxidizer controls, were incorporated with the oxidizer skid. The gas train and control system utilize Honeywell flame safeguard and gas train components. The control systems for the oven and oxidizer are integrated, so that full control of the system is accessible from the oven control panel.

The entire project from design to completed installation and commissioning was completed on time and on budget.

For more information on how Cire Technologies, Inc. can work with you to update or repurpose existing equipment, please click the Quick Connect button on this page or go to Request Info (click) page.