Multiple Smoke and VOC Oxidizer Installation

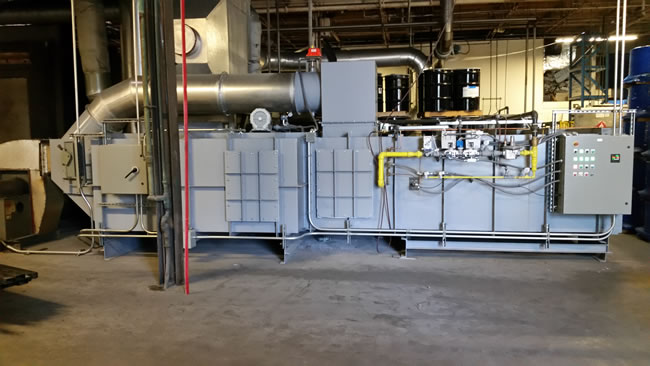

Cire Technologies is pleased to announce the completion of a year-long project to design, fabricate and install nine recuperative thermal oxidizers with direct feedback heat recovery, for a valued customer in North Carolina.

Our customer needed the oxidizers to be close to the exhaust of ten process ovens, due to the characteristics of the exhaust streams, which included organic particulate matter and phenol resin. The request to prevent potential fouling of the oxidizers led to the customer’s desire to implement dedicated oxidizers for each process oven and the use of recuperative thermal oxidizers. Our design raised each oxidizer directly above the process ovens on mezzanines, minimizing duct runs to the oxidizers.

Because of the energy intensive nature of running the recuperative units, we recommended and implemented waste heat recovery systems for the oxidizers. Each of eight of the oxidizers uses the hot exhaust air from the oxidizer stack directly back into the ovens as heated make-up air. Each heat recovery system included an insulated duct from the stack to a set of mixing dampers that mix the cleaned oxidizer exhaust with ambient air from the outside to provide heated make-up air to the ovens.

Attention to design, accounting for the extensive thermal growth of interior components and the stresses created by that growth, ensure the long life of our oxidizers. See burner support and heat exchanger expansion joint pictures below.

Cire Technologies was responsible for the complete turnkey project including the nine oxidizers, the support mezzanines, modifications to the process ovens and exhaust systems, make-up air ductwork and fans. All nine oxidizers were delivered on time and on budget.

Cire Technologies is proud of the quality of our equipment and our attention to energy efficiency. Perhaps you have an oxidizer project with a waste heat source you would like to explore uses for? We would love to hear from you.

Cire Technologies was tasked with designing, fabricating and starting up this new replacement burner system for a paper company in Brazil. This project included a Maxon, Crossfire, burner mounted in an insulated duct, the combustion air fan, a Maxon, Micro-Ratio, gas and combustion air control valve, a new double block and vent gas train and a new control system including a touchscreen HMI and communication capability. The burner is removable on a rolling frame from the side of the burner duct, through a bolt-on access door, allowing for easy maintenance.

Cire Technologies was tasked with designing, fabricating and starting up this new replacement burner system for a paper company in Brazil. This project included a Maxon, Crossfire, burner mounted in an insulated duct, the combustion air fan, a Maxon, Micro-Ratio, gas and combustion air control valve, a new double block and vent gas train and a new control system including a touchscreen HMI and communication capability. The burner is removable on a rolling frame from the side of the burner duct, through a bolt-on access door, allowing for easy maintenance.

This project, installed in Massachusetts, encompassed the design, fabrication, installation and start-up of a new process line for a web oxidizing process line. This turnkey installation included the web handling equipment, 3-pass and six temperature zone oven and an interactive computer control system. The process required gentle handling of a brittle product and the demanding service of oven operating temperatures up to 752°F (400°C).

This project, installed in Massachusetts, encompassed the design, fabrication, installation and start-up of a new process line for a web oxidizing process line. This turnkey installation included the web handling equipment, 3-pass and six temperature zone oven and an interactive computer control system. The process required gentle handling of a brittle product and the demanding service of oven operating temperatures up to 752°F (400°C).